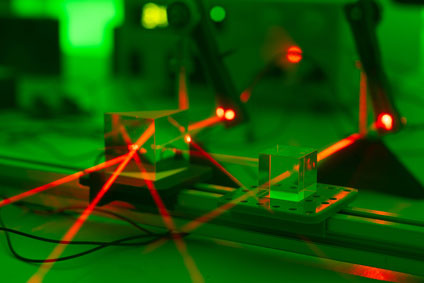

Evaluation of the target costs of a mechatronic laser measurement system in the concept phase

Earliest cost estimate with 4cost in the design workshop with maximum deviation of 4 % (series)

Initial situation & task

- New product development is planned

- First concepts and ideas are available

- At what cost can we manufacture?

- At what manufacturing costs is the break-even point?

Approach

- Ideas workshop with cost evaluation of the individual concepts

- Rough structural development (parts list)

- Evaluation of the individual components and assemblies

- Evaluation of assembly and test efforts

- Simulation and analysis of different scenarios

Results

- Clear elaboration of target costs

- The product was launched after two years

- Cost deviation between earliest estimate and actual production costs of approx. 4 %.

Parametric evaluation of tools and fixtures

4cost identifies cost potential of 30 %, supports negotiation and realises 25 % cost reduction

Initial situation & task

- A supplier was asked to provide a first ROM

- Management wants clarity on the value for money

- Internal estimates are based on “expert knowledge” without any transparency

Approach

- A parametric calculation is created from the technical descriptions (rough specifications)

- Creation of a rough structure

- Parametric evaluation of the individual components and assemblies

- Validation of assembly and test efforts

Results

- 4cost’s Should Costing has a delta of 30 % to ROM

- With 4cost’s technical negotiation support, a cost reduction of 25 % is achieved

Business case decision for an automatic box sorting system

4cost identifies cost reduction potential of 29 % with standardisation

Initial situation & task

- Determination of the investment costs

- Calculation of the break-even point compared to the semi-automatic solution

- Determination of different variants and dimensions

- Determination of the reduction potential with standardisation

- Determination of one-off costs (especially development and programming costs)

Approach

- Technical analysis of the existing specifications

- Cost evaluation of the existing rough concept

- Process survey of the current situation

- Conducting cost workshops with simultaneous cost evaluation of alternative solutions

- Elaboration of the decision paper

Results

- No break-even point achievable as a project order

- With standardisation: cost reduction potential of 29 % (material, production) possible

- Business case can be positively presented from a quantity of seven units upwards

- Alternative solution concepts with evaluation of implementation costs

Cost evaluation of a modified fibre processing plant when outsourcing to a low-wage country

Cost potentials of 15 % in engineering and 19 % in sourcing strategy according to 4cost analysis

Initial situation & task

- Predecessor model available

- Annual sales volumes and markets specified by the sales department

- Only rough idea of achievable target price

Approach

- Cost assessment of the existing plant

- Definition of the modifications (delta method)

- Cost evaluation of the adaptations

- Analysis of different sourcing strategies

- Evaluation of different assembly structures regarding production, logistics, pre-assembly and final assembly for different countries

- Consideration of ten years project duration including inflation/cost increase

Results

- Clear elaboration of a target price

- Cost potentials from engineering of 15 % identified

- Cost potentials from the sourcing strategy of over 19 % identified

Standardisation of the calculation scheme and introduction of a software-supported calculation method

Implementation of a homogeneous costing landscape implemented in ten weeks

Initial situation & task

- Heterogeneous costing landscape

- No uniform calculation scheme and no standardised methodology

- Different Excel-based solutions

- Data and know-how not centralised

- Little transparency

Approach

- As-is analysis and requirements concept

- Creation of requirement and functional specifications for software-supported calculation

- Adaptations to software and test

- Implementation

- Pilot phase

- Product training

- Rollout

Results

- Implementation of a homogeneous costing landscape in ten weeks

- Standardisation of costing scheme and methodology

- Transparent, traceable calculations

- Central data and file management with authorisation concept

- Bundled know-how

- Uniform reporting

- Detailed costing 23 % faster