Significant cost savings with 4cost

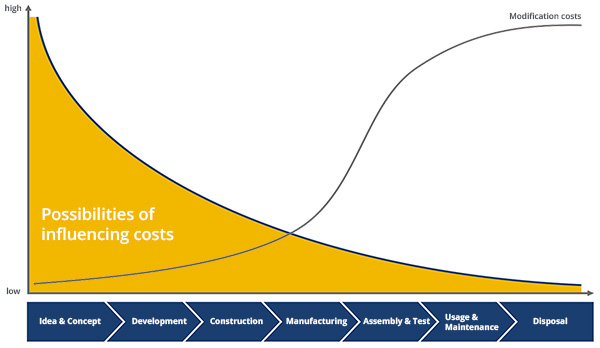

The relevance of value engineering, cost engineering, design-to-cost and calculation during development for industrial companies is of utmost important today. If you want to keep up with the growing global competition, you have to produce products with high customer value using the least possible resources. This requires a systematic optimisation of all processes in the entire product development process as well as in the subsequent use.

With the help of standardised value analyses, cost-down and should costing, 4cost’s value engineering uncovers maximum savings potentials in product costs at an early stage. Our innovative software solutions are designed and used for this – for consistent cost calculations right from the start of the project.

You can rely on our decades of experience from over 2,500 projects with renowned industrial companies worldwide.

The advantages of our value engineering at a glance

Fast and valid cost estimates

Cost-optimised from the start of the project. The use of our costing software solutions for end-to-end cost calculations enables us to provide you with valid cost estimates. A high degree of accuracy is ensured based on just a few pieces of information in early phases. Our cost reduction experts work with you to develop and evaluate different concepts and scenarios to find the best possible solutions throughout the entire product development process.

Agile team of experts

4cost provides you with experienced value analysts and technology specialists from the areas of development, design, production, project management, software programming, assembly, testing and integration as required. Collaboration with our cross-functional team of experts enables a neutral view of your projects, so that previously undiscovered potential is made visible and opportunities to increase innovation are opened up.

In addition to short-term support during peak loads of projects, our value engineers are also happy to provide your company with long-term, cross-project support in the development of cost-optimised products and the implementation of a company-wide standardised value analysis method.

Professional reports and recommendations

For a reliable business case and maximum decision-making certainty. On the basis of the analyses carried out by 4cost, you receive reports prepared according to your needs, in which we display all relevant results for a quick overview and comparisons. Based on this, our experts make concrete recommendations for action and weigh up the pro and cons of the opportunities and risks for you.

Support for purchasing

Make full use of your savings potential in purchasing. Thanks to our innovative, rapid cost analysis of purchased parts (should costing), you can optimise your purchasing strategies, make well-founded make-or-buy decisions and create a secure basis for negotiations with suppliers. The experts at 4cost will provide and help you with the necessary arguments to lower your purchase prices. We are also be very happy to support you personally in negotiations.

We support you in all phases of product development

Concept phase

The longest lever for optimising product costs is here.

Evaluate different concepts of design with us and its influence and requirements on specifications to achieve the cost optimum.

Development phase

Optimisations can be achieved by exchanging parts, using common parts, using commercial off-the-shelf (COTS) or working out material alternatives. Design-for-Manufacturing (DFM) and Design-for-Assembly (DFA) as well as continuous cost analyses with our value engineers are standard.

Ready for series production

As soon as approved specifications, designs and first quotations are available, our measures to support purchasing take effect. There are numerous approaches to optimising the procurement situation. Particularly noteworthy here are technology-neutral benchmarks and the derivation of suppliers’ cost structures and surcharge rates.